Woodwork machinery can be costly, after having invested a big part of your workshop’s budget on top quality machinery, you would be very disappointed to have it breakdown or stop working. It is therefore wise to keep it in good working condition.

Ensuring you take the time to incorporate maintenance time into the day-to-day running of your workshop, will prolong the working life your machines and help to prevent any inconvenient machine breakdowns. Saving you money and time, long-term.

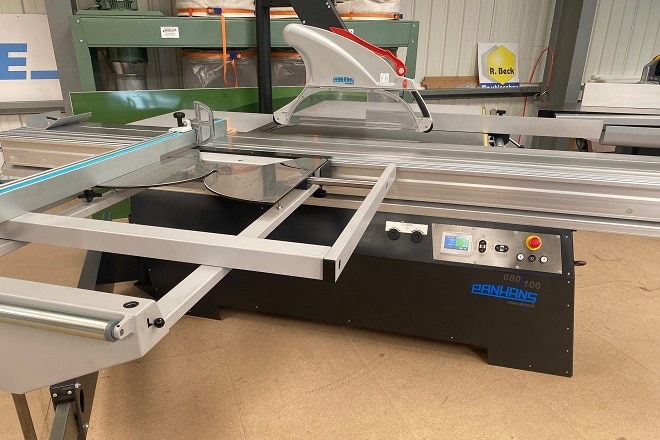

Woodwork machinery maintenance

When carrying out maintenance on any machine, this should be completed by a trained and qualified engineer, who has the knowledge to spot errors and make repairs. The maintenance required on your woodwork machinery will differ between individual machines.

Some may only require small amounts of maintenance throughout the year, while other, bigger, machines may require more attention and observation (both from your workshop team and engineers). It is important to keep records of all maintenance activities carried out on each machine, to ensure nothing has been missed and you are adhering to health and safety standards.

Sometimes the machine manufacturer will have recommended maintenance instructions which must be followed to preserve the quality of the machine. Any maintenance schedule should be reviewed regularly to ensure a preventive approach, rather than reactive maintenance, is achieved. A piece of well-maintained equipment will always last longer and will be more efficient.

Top tips for machine maintenance

- Regularly sharpen or change your blades – although it may be tempting to push a cutting blade to its limits to save a few pounds. You should consider how much longer cutting will take with a blunt blade and the extra strain on the machine motor. Using a sharp blade will not only provide you a greater quality cut but will prevent your machine from overworking and potentially slowing down as a result.

- Check over the machine before starting to ensure nothing is restricting movement – Before you begin cutting it is important to make sure that all moving parts are free and turning or moving as they should. Any moving parts on your machine should be lubricated as per your user guide.

- Clean your wood shavings and debris after use – After using your machine, you must clean the wood shavings and debris to prevent the risk of fire or damage, as a result of overheating. This is an important step in both machine maintenance and health and safety regulations. Your machines will give you better service for longer if you avoid the build-up of resin and muck around the machine, rust and moisture damage is more likely to cause problems on a dirty poorly maintained machine.

- Carry out routine checks prior to starting work and always when machines have been idle for any left of time – This will ensure nothing has been broken or damaged in the time you have not been running the machine and will prevent any injury.

Why machine maintenance is important

Preventative maintenance is better than paying for repairs and losing the time and money of breakdown repairs. Prevention is always better than cure. It is also simple and cost-effective to have these booked on a routine for each individual machine, based on the machine workload. This will reduce the risk of breakdown and extend the life of your woodwork machinery. Your workshop will benefit from this, as by avoiding breakdowns, your machines will run efficiently.

- Extend equipment lifespan.

- Reduce the need for having to purchase new equipment.

- Prevent unplanned downtime which can be costly and interrupt the manufacturing process.

- Avoid the need for expensive repairs due to negligence.